Any modern organization cannot compete and meet the demands of the market if its processes and activities are not sufficiently digitized. In fact, much of the three kinds of waste—Muda, Mura, and Muri—can be eliminated by digitizing processes and operations. At SK Banerji, we provide Digital Transformation & Sustainability Consulting to empower organizations by harnessing the power of data and AI. We leverage the power of data after reaching a certain level of Statistical Process Control (SPC) maturity to gain agility in sync with the market needs.

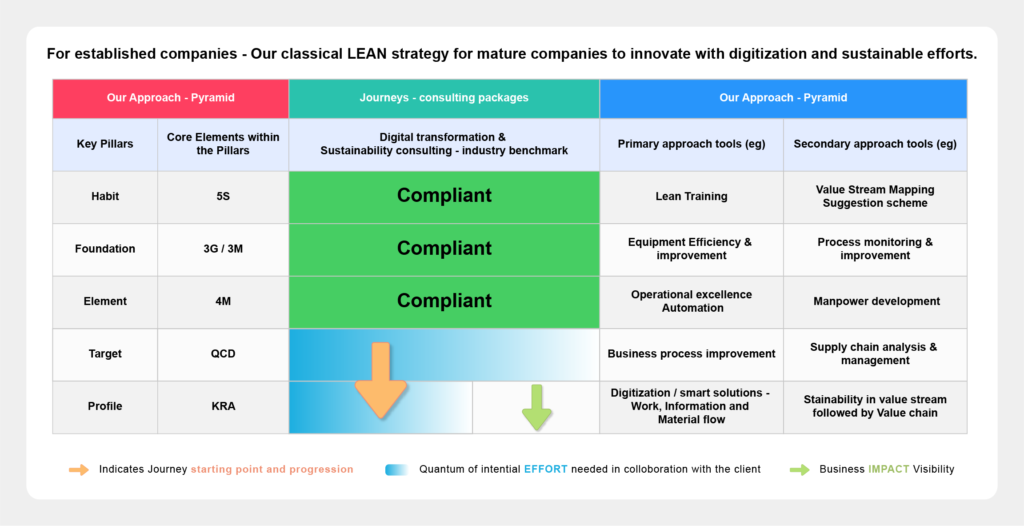

Mature organisations that have been running conventional and near-rigid operations are more in need to fix their faulty lines by adopting the ‘LEANer’ path of improvement and modernization.

To ensure that our clients thrive in the transformative age and scale success, we follow the Plan-Do-Check-Act for their Equipment Efficiency Improvement and Digitization and Automation at all levels.

At this stage, we plan initiatives that can lead to a successful digital transformation and business goals. We prepare a digital strategy that will outline the priorities, deliverables, outcomes, and timelines in your organization’s digital journey. We begin with the preparation of Value Stream Mapping (VSM) for the current state of the enterprise.

The second step is the implementation phase. After identifying the areas that need to be restructured, we work on specific areas as per the roadmap to reap the potential benefits.

During the check phase, we measure & control processes and operations by employing our 4T program:

In this stage, we take relevant Corrective And Preventive Actions (CAPA) to standardise or improve the process. The actions are rendered via:

Once the solutions become a reality, it is wise to sustain them with continuous improvements.