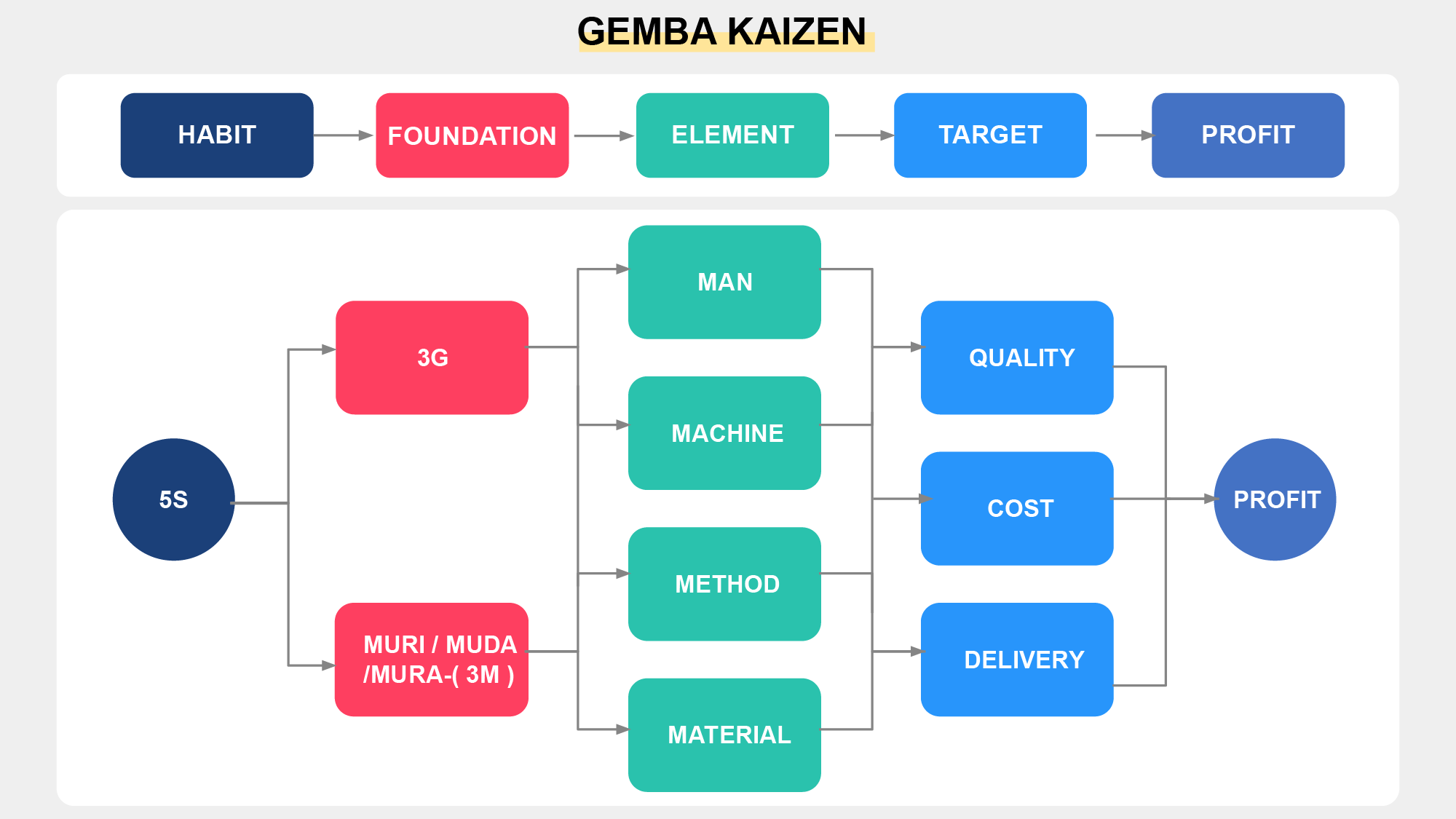

SK Banerji’s Goal Achieving Approach is a strategic planning framework that breaks down the overall objective of the business into hierarchical actions required to achieve the ultimate goal. It comprises 5 processes of inculcating habit formation and optimising the resources with dedicated capabilities to achieve the desired target and maximise profits.

SK Banerji’s Goal Achieving Approach

At SK Banerji’s ecosystem, we work from the grassroots level.

01

Habit Formation:

We don’t see the methods and practices of an organisation as a series of events but as habits. We believe that organisations are made up of people first, hence, the change must begin from there to succeed and sustain. We train the employees in forming habit loops such as management, improvement, and willpower to operationalize its fundamental principles. The people-focused habits inhibit the philosophy of LEAN that facilitates the ground-level staff with capabilities that help them persist and adapt.

02

Laying Foundation:

We believe that the elimination of any and all kinds of waste is the key to operational efficiency. We aim at identifying and eliminating waste (Muri, Muda, Mura) to improve quality, safety and efficiency and create a sustainable process. To attain so, we incorporate the 5s (sort, set in order, shine, standardise and sustain) LEAN tool that helps to declutter the workplace and creates room for better organisation and planning.

03

Identifying Problems:

Every reaction comes with a cause and 4M (Material, Method, Machine, Man) is attributed to the causes of inefficiency and redundancy in any organisation that add up to a huge economic loss. SK Banerji focuses on understanding the depths of the 4Ms as possible causal elements in any kind of discrepancy and stabilising them as a foundation for improvement.

04

Achieving Targets:

While many companies believe that it’s impossible to balance higher quality, and reduce cost and delivery time simultaneously, SK Banerji rejects the idea that you need to sacrifice either quality, cost or delivery to achieve the other two. We can absolutely attain all three by eliminating non-value-added activities, flexible manufacturing and just-in-time scheduling and manufacturing.

05

Maximising Profits:

With the right toolset and practices, we focus only on value-added activities, eliminate wastes of all kinds and rely on continual improvement and standardisation. We help you create an adaptable business model that runs most efficiently to deliver the most value to the clients and customers.